Directly connected to the output file of the CAD system thereby enabling the CAM to automatically recognize new designs and include them in the part list for further machining and management.

Supports clamping devices that allow horizontal processing of dental parts (C clamp). Utilization of lateral drilling and lateral details can now be fully automated.

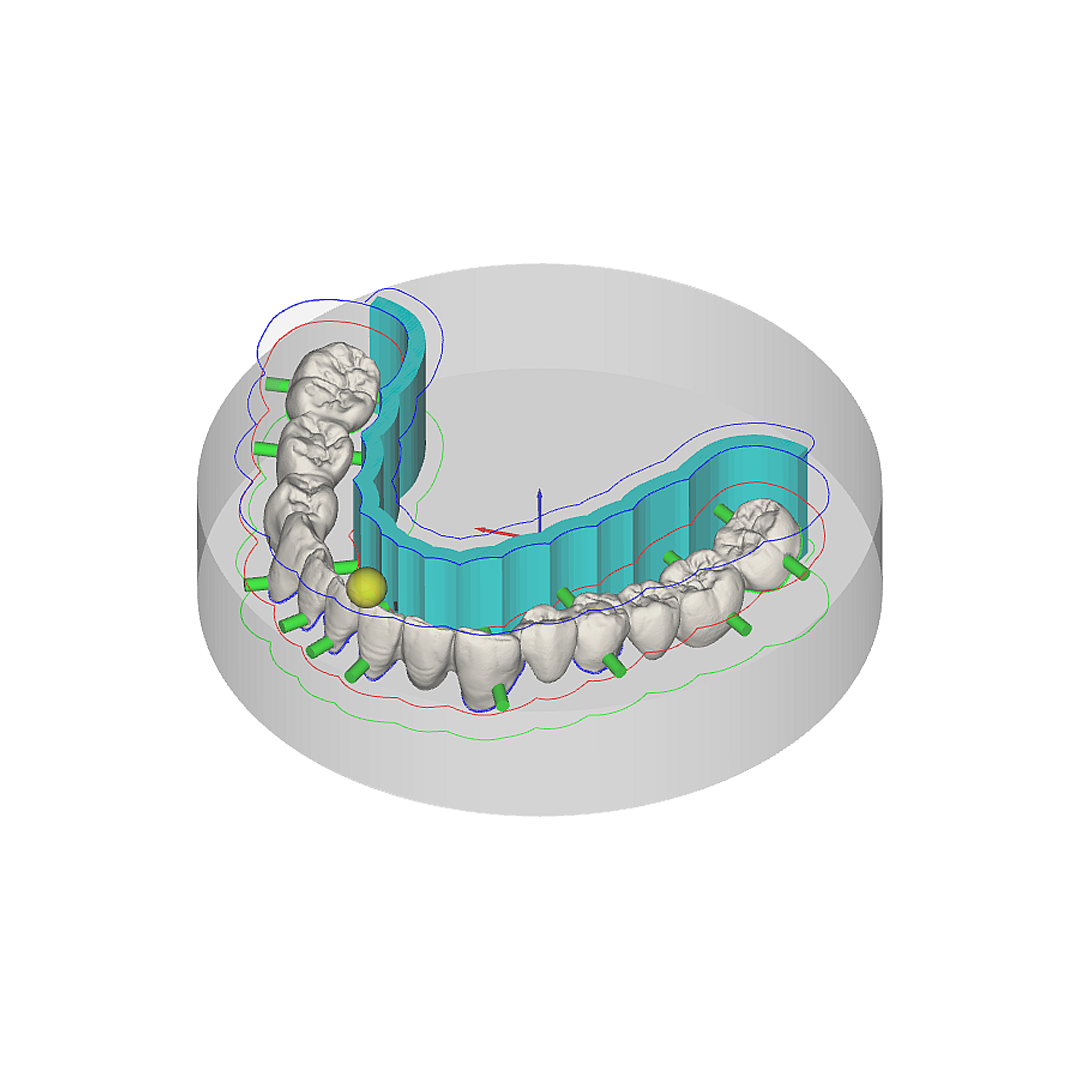

Areas can be automatically selected, which saves time in implementing non-accessible or difficult-to-access areas.

Significant time savings in manufacturing dental parts of different materials can be achieved. This is due to the controllable removal rate.

Implant modules, customized abutments, implant bridges and bars can be manufactured from circular blanks. Due to intelligent categorization, only one master template is required for all systems.

Features interfaces to the CAD systems from 3Shape and Exocad. With the utilization of CAD metadata, the entire workflow can be simplified and the cycle time can be reduced significantly. It is possible to start hyperDENT® directly from 3Shape.

With S.I.N. 360’s professional support and customer service, you will have the assistance needed to maximize the performance of your hyperDENT and the knowledge and skills to achieve outstanding results.